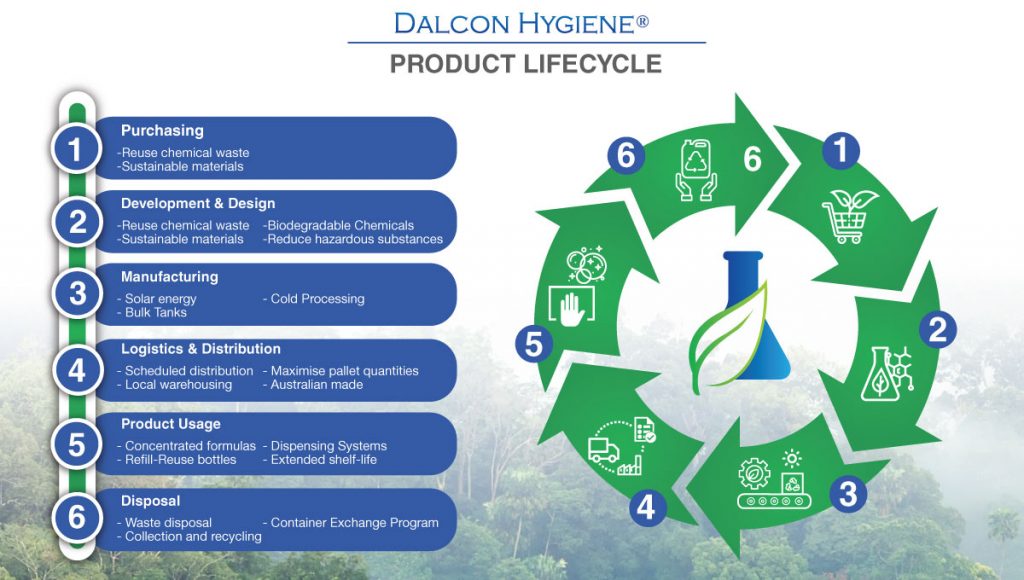

At Dalcon Hygiene, we work with a variety of sensitive products. By nature, chemical products can be quite volatile, presenting threats of danger to both our natural ecosystems and the people and animals who dwell within them. Our prolonged success over the last 70 years is largely due to one of our key core values – sustainability. This article will briefly explore Dalcon Hygiene’s product lifecycle in order to paint a general picture of how our products progress from their raw state into the final, high-quality good that you open up when it’s delivered to you.

1. Purchasing

Green Procurement: Green procurement essentially means that we strive to purchase raw materials, packaging and all other products associated with our final product that are environmentally sustainable as well as utilising contractors that also operate sustainably.

Renewable Raw Materials: At Dalcon, we manufacture final products from raw components we obtain from other organisations. We remain diligent in our analysis of our supply chain to ensure that each of our suppliers adheres to our high sustainability standards.

2. Development & Design

Reusing Chemical Waste: Where possible, we seek to minimise wastage by reusing what we can in subsequent product design and manufacture.

Sustainable Materials: Our sustainable practices extend beyond the contents of our packaging to the actual packaging itself. Wherever possible, we utilise recyclable materials for our packaging to minimise our environmental impact.

Biodegradable Chemicals: Biodegradable is the term given to something that is capable of being broken down by bacteria or other living organisms, thereby reducing pollution. Where possible, we prioritise use of biodegradable chemicals to minimise our environmental footprint.

Reducing Hazardous Substances: While it’s not always possible for our heavier duty products, we are constantly looking to innovate in order to reduce the amount of hazardous substances we use in the formulation of our products.

3. Manufacturing

Solar Energy: As part of our commitment to minimising our environmental footprint, we power all our operations with clean energy provided from renewable sources. Our solar panels provide approximately 50 kw/hr of clean green energy.

Bulk Tanks: We house many of our more popular chemicals in large bulk tanks in our factory to ensure we always have available stock of the products our customers love most.

Cold Processing: Cold processing is just what it sounds like. By reducing the heat required for the processing of most of our chemical products, we are able to substantially minimise our carbon footprint.

4. Logistics and Distribution

Scheduled Distribution: We undertake local distribution from our factory in Smithfield while maintaining strong relationships with highly reputable distributors throughout Australia and overseas to ensure delivery times are kept to a minimum.

Local Warehousing: Holding stock in our own warehouse allows for better inventory management, meaning we are able to supply our customers with their desired products when and as they need.

Maximise Pallet Quantities: Stringent packing methods result in the most efficient use of pallet deliveries, ensuring we are able to get more products out in a shorter period of time.

Australian Made: All of our chemical products are 100% Australian made at our factory in Smithfield, Sydney.

5. Product Usage

Concentrated Formulas: By focusing on manufacturing concentrates, we can reduce the size and amount of packaging we use, facilitating easier distribution and further reducing our environmental impact.

Refill-Reuse Bottles: We provide pump and spray bottles that can easily be refilled and reused, saving unnecessary packaging wastage, and creating convenience for our customers.

Dispensing Systems: Our dispensing units help control the amount of chemical concentrate for easier dilution and less wastage. Additionally, by having mechanically controlled dispensing, the risk to human health and safety is minimised.

Extended Shelf-Life: Our products are made to last, reducing environmental impact and saving our customers money.

6. Disposal

Waste Disposal: We dispose of all waste thoughtfully and carefully, ensuring that disruption to natural ecosystems is kept to a minimum.

Collection and Recycling: We collect and recycle our packaging where possible. In instances where we are unable to enter into a container exchange, we arrange for all of our recyclable material to be collected and recycled ethically and safely.

Container Exchange Program: As our packaging is recyclable and reusable, we encourage container exchanges so that we may re-use containers. The cost savings this creates are passed on to our customers and stops perfectly good quality containers from unnecessary disposal.

Hopefully, this post has helped provide a greater understanding of exactly how Dalcon Hygiene’s product lifecycle and how it embodies our core values of innovation, sustainability and customer service to reduce our environmental footprint while providing the best possible experience to our customers. To find out more about our commitment to sustainability, click here.